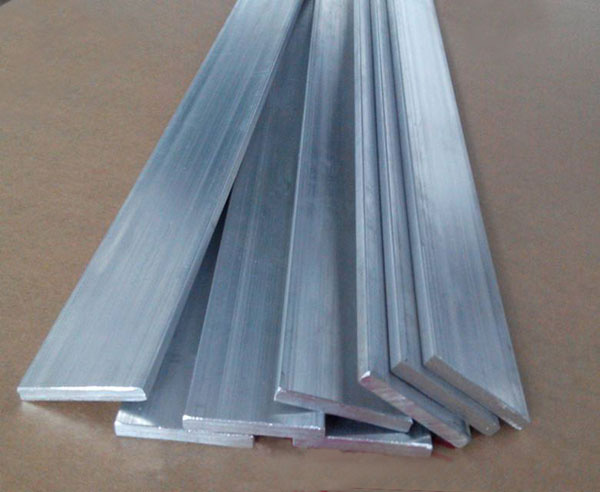

Extruded aluminum flat bar 1060 6061

Extruded aluminum flat bar is a type of aluminum product that is created by forcing heated aluminum through a die with a specific cross-sectional profile, resulting in a long, straight bar with a flat surface and uniform thickness. This process, called extrusion, allows for the creation of aluminum bars with precise dimensions and consistent quality.

The two most common models of extruded aluminum flat bars are 1060 and 6061.

Extruded aluminum flat bars are commonly used in construction, manufacturing, automotive, and other industries due to their lightweight, corrosion-resistant, and easily machinable properties. They can be further processed, cut, drilled, or shaped according to specific needs in various applications.

Features of extruded aluminum flat bar 1060 6061

Light weight: Aluminum is much lighter than steel, so extruded aluminum flat bars are easier to handle and transport, especially suitable for applications where lightweighting is required.

Corrosion Resistance: Aluminum forms a protective oxide layer when exposed to air, giving it excellent corrosion resistance. This property makes extruded aluminum flat bars suitable for harsh outdoor environments and marine applications.

High strength-to-weight ratio: Although aluminum is relatively light, it has very good strength. Extruded aluminum flat bars have a high strength-to-weight ratio, making them suitable for structural applications where strength is critical.

Workability: Aluminum is easy to process, which allows extruded aluminum flat bars to be precisely cut, drilled and formed to meet specific design requirements.

Versatility: Extruded aluminum flat bars are available in a variety of sizes and can be customized, providing versatility for a wide range of applications in industries including construction, automotive, aerospace and electronics.

Excellent Thermal and Electrical Conductivity: Aluminum conducts heat and electricity very well, so extruded aluminum flat bars are suitable for applications that require thermal or electrical conductivity.

Recyclability: Aluminum is highly recyclable. As a recyclable material, extruded aluminum flat bars contribute to sustainable development and reduce environmental impact.

Cost-Effectiveness: While aluminum may have a higher initial cost compared to other materials, it can result in cost savings in the long run due to its excellent properties.

Application of extruded aluminum flat bar 1060 6061

Structural components: Extruded aluminum flat bars have high strength and strong corrosion resistance, and can be used as structural components for frames, supports, decorations, etc.

Transportation: Extruded aluminum flat steel is used in automotive, aerospace and other transportation sectors, such as body panels, chassis components, frames and marine accessories. Their high strength-to-weight ratio helps reduce overall vehicle weight and improve fuel efficiency and performance.

Electrical and Electronics: Aluminum flat bars are used in busbars, heat sinks, enclosures and mounting brackets in electrical and electronic applications. Its excellent thermal and electrical conductivity make it ideal for efficient heat dissipation and current carrying.

Manufacturing and Machinery: Extruded aluminum flat bars are used in manufacturing equipment, machinery and industrial tools for structural supports, guide rails, mounting brackets and other components. Their processability allows for easy customization and integration into various manufacturing processes.

Construction and Decoration: Aluminum flat strips can be used in construction and interior design, such as handrails and railings.

Automation systems and robotics: Aluminum flat steel is used in automation systems, robotics and machinery for structural frames, robot arms, conveyor systems and support structures. Their lightweight nature and high strength make them ideal for dynamic sports applications.

Renewable Energy: In the renewable energy sector, extruded aluminum flat bars are used in solar panel frames, wind turbine components and mounting systems. Their lightweight and corrosion-resistant properties help extend the service life of renewable energy systems in harsh environmental conditions.