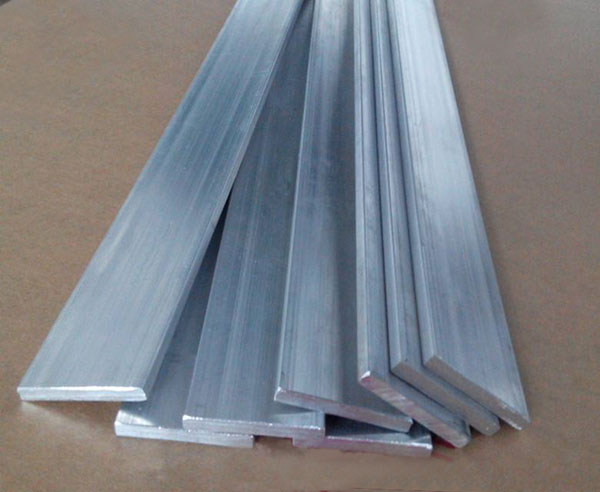

6061 T6 Aluminum Flat Far Busbar

Pure aluminium has a conductivity of about 65% IACS (International Annealed Copper Standard)

Alloy 6061. This heat treatable wrought alloy is recognised internationally as providing the optimum combination of strength and electrical conductivity for busbar.

Temper T6

This is solution heat treated and artificially aged to max. mechanical property levels.

Thermal Capacity

The thermal storage capacity of aluminium is 0.214 cal/gram/°C. For copper it is 0.092 cal/gram/°C. Therefore aluminium has a thermal storage capacity of more than 2-3 times that of copper. This is used to advantage in wound transformers, as aluminium can withstand more surge and overload currents.

Conductivity

When the density of copper (8.89 gm/cm²) is compared to aluminium (2.91gm/cm²) and taking into consideration the conductivity ratio of aluminium to copper of 57% for grade 6101 aluminium, aluminium has approximately 1.85 times that of copper. Copper has a greater conductivity on an equal volume, cross sectional area basis.

Mechanical Strength

Aluminium does have a lower tensile strength (37%) than copper for the same cross section of material. However, approximately 66% greater cross-section of grade 6101 aluminium is required to carry the same amount of current as would be required for a copper conductor, so the larger cross-section of aluminium approaches the tensile strength of copper for a given ampacity.

Weight

Aluminium is approximately 30% of copper of the same size. The charts on page 13 show weights per metre for standard rectangular aluminium and copper bars.

Chemical composition

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Each | Total |

|

0.40- 0.80 |

Max. 0.7 |

0.15- 0.40 |

Max. 0.15 |

0.8- 1.2 |

0.04- 0.35 |

Max 0.25 | Max 0.15 | Max 0.05 | Max 0.15 |

Detail information

Alloy : 6061

Temper : T3-T8

Surface Treatment: Zinc, Nickel, Tin, Silver, etc.

Tolerance: +/- 0.1mm

Length: up to 6m

Width: 10mm - 200mm

Thickness: 0.15mm - 40mm

Processing: Stamping, Bending, Drilling, Threading, Polishing, etc.

Application : Door & Window, Decorations,Heat Sink,Glass Wall, Transportation Tools;

Properties

Hardness 175 to 230 Hv200

Elongation in 50mm 15 to 25%

Tensile strength 620 MPa

Internal stress 3.4 – 620 MPa

Deposit appearance Semi-matt

Deposit thickness 10 microns

Features

Lightweight, with smooth finish and defined edges

General purpose material

Excellent candidate for most processing techniques

Good corrosion resistance

Excellent at resisting moisture and strong for its light weight

Specifications:

Brinell: 95

Tensile: 45,000 +/-

Yield: 40,000 +/-

Sizes: 2ft, 4ft, 6ft, 8ft, 12ft

Thicknesses: 0.250 inch (6.35 mm)

Tensile strength: 42,000 psi (290 MPa)

Mechanical properties

| Temper |

Thickness e |

Yield stress Rp0.2 (mpa) |

Tensile strength Rm (mpa) |

Elongation A[%] |

Elongation A50mm [%] |

Hardness HB |

| T4 | e<=25 | 110 | 180 | 15 | 13 | 65 |

| T6 | e<=5 | 240 | 260 | 9 | 7 | 85 |

| 5<e<=25 | 240 | 260 | 10 | 8 | 85 |

Physical properties (approximate values, 20℃)

|

Density [kg/m3] |

Melting range [℃] |

Electrical Conductivity [MS/m] |

Thermal Conductivity [W/m.K] |

Co-efficient of Thermal expansion 10-6/k |

Modulus of elasticity [GPa] |

| 2700 | 585-640 | 22-30 | 170-200 | 23 | ≈70 |