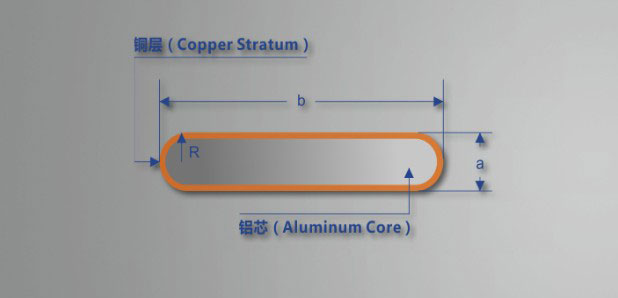

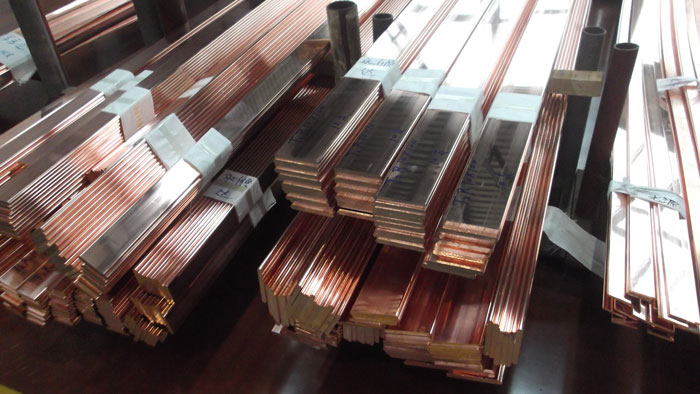

Copper Clad Aluminum Busbar

Material

The copper clad aluminum bus shall be produced by the standard of GB/T 5231, and the copper content shall not be less than 99.90%.The material of aluminum core shall conform to the provisions of GB/T 1196, and the content of aluminum shall be no less than 99.70%.

Our Copper Clad Aluminum Busbar

2. Volume ratio: 20% copper, 80% aluminum

3. Mass ratio: 45% copper, 55% aluminum

4. Material: T2 copper (SGS 99.98%), 1070 aluminum

5. Density: 3.94 g/cm3 plus or minus 3.2%

6. Carrying capacity: 86% of the pure copper busbar

7. The DC resistivity: 0.02554 or less Ω was/m (soft)

8. Elongation: 11% or greater (soft state), 1.5% or greater (hard state)

9. Tensile strength: greater than or equal to 90MPa (soft state), greater than or equal to 110MPa (hard state)

10. Shear strength of interface bonding between copper and aluminum is greater than or equal to 42MPa

11. Yield stress: 44mpa-54mpa (soft state), 152mpa-179mpa (hard state)

12. Elastic coefficient: 71GPa

13. Thermal conductivity: 0.58 Cal/Cm/Sec / ℃

Specification:

| Weight Display in Common Specification | ||||||||

| Specification a*b(mm) | 3*30 | 3*40 | 3*50 | |||||

| Weight/meter(kg) | 0.31 | 0.42 | 0.53 | |||||

| Specification a*b(mm) | 4*40 | 4*50 | 4*60 | 4*80 | ||||

| Weight/meter(kg) | 0.56 | 0.7 | 0.84 | 1.12 | ||||

| Specification a*b(mm) | 5*40 | 5*50 | 5*60 | 5*80 | ||||

| Weight/meter(kg) | 0.7 | 0.875 | 1.05 | 1.4 | ||||

| Specification a*b(mm) | 6.4 | 6*50 | 6*60 | 6*80 | 6*100 | |||

| Weight/meter(kg) | 0.84 | 1.05 | 1.26 | 1.68 | 2.1 | |||

| Specification a*b(mm) | 8*50 | 8*60 | 8*80 | 8*100 | 8*120 | 8*200 | ||

| Weight/meter(kg) | 1.4 | 1.68 | 2.24 | 2.8 | 3.36 | 5.6 | ||

| Specification a*b(mm) | 10*60 | 10*80 | 10*100 | 10*120 | 10*150 | 10*200 | 10*250 | 10*300 |

| Weight/meter(kg) | 2.1 | 2.8 | 3.5 | 4.2 | 5.25 | 7 | 8.75 | 10.5 |

Advantages of Copper Clad Aluminum Busbar(CCA busbar)

1. Good conductivity: Compared with the electrical property of pure copper busbar, AC carring capacity of 15%-20% copper volume copper clad aluminum busbar is more than 85% of the red copper busbar.

2. Light weight: The density of the CCA busbar is 37%-40% of the pure copper busbar, the length is 2.5-2.6 times compared with pure copper busbar in the condition of same weight. The weight ratio between pure copper busbar and bimetallic copper busbar is 2.6:1.

3. Good mechanical property: Good ductility, CCA busbar do not exist wrinkle,bubble or surface crack in the process of bending. operational performance of the product can be assured.

4. strong bonding between copper and aluminum: Two different metallic material reach permanently atom bonding in the specific environmental temperature. Do not exist any physical defects.

5. Good extensibility and reliability: It has plasticity through special heating process technology and be beneficial to punching, shear, bend process. Tining, Zincing and silver coating process to ensure corrosion resistance.

6. Best selectivity: Save copper resource to reduce production and matching cost. It has no contamination, it is environmental friendly.Our company can manufacture various specification copper clad aluminum busbar. We have superior production equipment to fulfil technology and industry requirement completely.

PROPERTIES

DRILLING

Recommended drill characteristics

Cutting speed: 50m/min.

Drill cutting angle:135º-140º.

Helix angle: 45º.

Lubricant and coolant white spirit.

CUTTING

Copper-Clad Aluminium (CCA) busbar can be cut using methods that apply to aluminium. Grinding of cut saw to a trapezoidal shape gives good results and deburring is not necessary.

Cutting speed: 50-90 m/sec.

Lubricant and coolant white spirit.

BENDING

N.B. Above factors are for bending normal to the plane.

For edge bending the forming tool radius should be multiples of the width w.

| Min. ultimate tensile strengh | 30-170 | MN/㎡ |

| Modus of elasticity | 85x10³ | MN/㎡ |

| Density at 20 ℃ | 3,63x10³ | KG/㎡ |

| Max. electrical resistivity at 20 ℃ | 2,65x10-8 | Ωm |

| Min. electrical conductivity at 20℃ | 37,7x106 | 1/Ωm |

| 65 | %IACS | |

| Temp. coefficient of resistance at 20℃ | 4,01x10-3 | 1/oC |

| Coeff. of linear thermal expansion º 20-100 | 21,9X10-6 | 1/oC |

| Melting point | 658 | ℃ |

| Specific heat | 711,7 | J/kg/ºC |

| Thermal conductivity | 2,38X106 | W/m2/ºC |

DRILLING

Recommended drill characteristics

Cutting speed: 50m/min.

Drill cutting angle:135º-140º.

Helix angle: 45º.

Lubricant and coolant white spirit.

CUTTING

Copper-Clad Aluminium (CCA) busbar can be cut using methods that apply to aluminium. Grinding of cut saw to a trapezoidal shape gives good results and deburring is not necessary.

Cutting speed: 50-90 m/sec.

Lubricant and coolant white spirit.

BENDING

N.B. Above factors are for bending normal to the plane.

For edge bending the forming tool radius should be multiples of the width w.