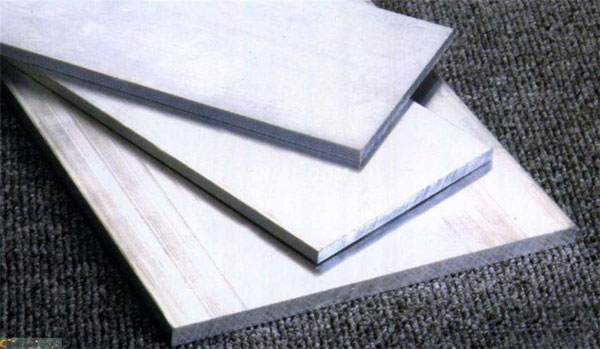

6101 Aluminum Flat Bar Busbar

Pure aluminum has a conductivity of about 65 percent of the International Annealed Copper Standard (lACS). Aluminum can be produced 99.99 percent pure; however, this purity is costly to achieve and the mechanical properties are low.

After World War II, a new conductor alloy, 6101, was developed which has considerably higher yield strength and better creep resistance than 1350. The alloy contained magnesium and silicon for high mechanical strength without significant reduction in conductivity. The strength of this alloy (6101) is obtained by suitable heat treatment, occasionally combined with some cold work.

Temper T6

This is solution heat treated and artificially aged to max. mechanical property levels.

Thermal Capacity

The thermal storage capacity of aluminium is 0.214 cal/gram/°C. For copper it is 0.092 cal/gram/°C. Therefore aluminium has a thermal storage capacity of more than 2-3 times that of copper. This is used to advantage in wound transformers, as aluminium can withstand more surge and overload currents.

Conductivity

When the density of copper (8.89 gm/cm²) is compared to aluminium (2.91gm/cm²) and taking into consideration the conductivity ratio of aluminium to copper of 57% for grade 6101 aluminium, aluminium has approximately 1.85 times that of copper. Copper has a greater conductivity on an equal volume, cross sectional area basis.

Mechanical Strength

Aluminium does have a lower tensile strength (37%) than copper for the same cross section of material. However, approximately 66% greater cross-section of grade 6101 aluminium is required to carry the same amount of current as would be required for a copper conductor, so the larger cross-section of aluminium approaches the tensile strength of copper for a given ampacity.

Flat wise Bending Radius

| Type of Bar | Alloy and Temper | Thickness (mm) | Radius min. |

|

Extruded |

1350-H11 | All | 1 * thickness |

| 6101-H11 |

0.250-0.750 0.751-1.000 |

1 * thickness 2 * thickness |

|

| 6101-T6 | 0.125-0.375 |

2 * thickness 21/2 thickness |

|

| 6101-T61 |

0.125-0.500 0.501-0.749 0.750-1.000 1.001-1.625 |

1 * thickness 2 * thickness 3 * thickness 4 * thickness |

|

| 6101-T63 |

0.125-0.375 0.376-0.500 0.501-1.000 |

1 * thickness 11/2 thickness 21/2 thickness |

|

| 6101-T64 |

0.125-0.750 0.751-1.000 |

1 * thickness 2 * thickness |

|

| 6101-T65 |

0.125-0.500 0.501-0.749 |

1 * thickness 2 * thickness |

|

| Rolled | 1350-H12 | All | 1 * thickness |

| Sawed plate | 1350-H112 | All | 1 * thickness |

Applicable to widths up through 6 inches in the T6,T61,T63 and T65 temper and to widths up through 12 inches for all other listed tempers. Bend radius for greater widths are subject to inquiry.

Mechanical Properties of Aluminum Bus Conductor and Related Alloys

(The Aluminum Association ; ASTM B 236, B 241, and B 429; and Manufacturer’s Listings)

(The Aluminum Association ; ASTM B 236, B 241, and B 429; and Manufacturer’s Listings)

| Product | Alloy/Temper |

Thickness in Ultimates |

Tensile Strength (ksi) At 20 (68。F) |

Typical Ultimate |

Typical Yield |

Typical(a) Elongation (Percent - in 2 in. Or 4 Dia) |

|

|

Min. Ultimate |

Min. Yield |

||||||

|

Extruded rod, bar tube, pipe and shapes |

1350-H111 | All | 8.5 | 3.5 | 35.0 | ||

| 6101-T6 | 0.125-0.500 | 29.0 | 25.0 | 32.0 | 28.0 | 15.0 | |

| 6101-T61 |

0.125-0.749 0.750-1.499 1.500-2.000 |

20.0 18.0 15.0 |

15.0 11.0 8.0 |

||||

|

6101-T63 6101-H111 6101-T64 6101-T65 |

0.125-0.500 0.250-2.000 0.125-1.000 0.125-0.749 |

27.0 12.0 15.0 25.0 |

22.0 8.0 8.0 20.0 |

14.0 | 11.0 | ||

| Extruded pipe(c) |

6061-T6 6063-T6 |

Pipe size 1.0 & over Pipe sizes,all |

38.0 30.0 |

35.0 25.0 |

45.0 35.0 |

40.0 31.0 |

10.0 min 8.0 min |

| Rolled bar | 1350-H12 | 0.125-1.000 | 12.0 | 8.0 | 14.0 | 12.0 | |

| Sawed-plate bar or sheet | 1350-H112 |

0.125-0.499 0.500-1.000 1.001-3.000 |

11.0 10.0 9.0 |

6.0 4.0 3.5 |

10.0min 16.0min 22.0min |

||

|

Rolled sheet (for shearing or forming) |

1350 1350-H12 1350-H14 |

0.020-0.249 |

8.0 12.0 14.0 |

12.0 14.0 16.0 |

4.0 12.0 14.0 |

20-30 min 4-9 min 3-6 min |

|

|

1350-H16 1350-H18 |

0.020-0.125 |

16.0 18.0 |

18.0 | 16.0 |

2-4 min 2-4 min |

||

| Cast Alloy for Bus |

1350-F 1050 |

1 in. And up | 8.5 | 3.5 | 35.0 | ||

| Cast Alloy for Fittings | A356.0-T61 | 37.0 | 5.0 | ||||