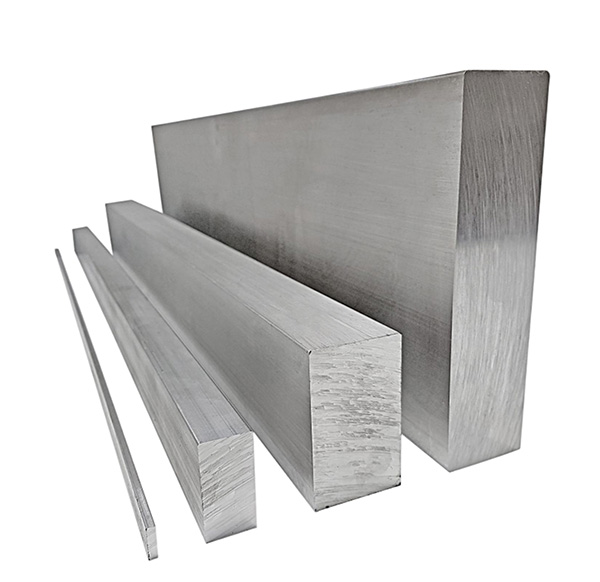

EC grade aluminum busbar

There are many types of aluminum busbars. Electrical grade aluminum busbars usually refer to those with an aluminum content greater than 99.5%, because the higher the aluminum content, the better the conductivity, such as 1060 and 1350.

Comparison of 1060 and 1350 Aluminum Busbars

As conductive aluminum busbars, 1060 and 1350 share the following characteristics:

High Purity: Both belong to the "industrial pure aluminum" series, with extremely high aluminum content (≥99.6%) and low impurities.

Excellent Conductivity: Due to their high purity, both have excellent conductivity, far exceeding that of other aluminum alloys (such as 6061).

Good Corrosion Resistance: High-purity aluminum quickly forms a dense oxide film in air, which prevents further oxidation of the underlying metal, resulting in excellent corrosion resistance.

High Plasticity and Easy Processing: Both are relatively soft, making them easy to process through bending, stamping, shearing, and other forming processes.

Economical: Both offer significant weight and cost advantages over copper busbars.

Excellent Conductivity: Due to their high purity, both have excellent conductivity, far exceeding that of other aluminum alloys (such as 6061).

Good Corrosion Resistance: High-purity aluminum quickly forms a dense oxide film in air, which prevents further oxidation of the underlying metal, resulting in excellent corrosion resistance.

High Plasticity and Easy Processing: Both are relatively soft, making them easy to process through bending, stamping, shearing, and other forming processes.

Economical: Both offer significant weight and cost advantages over copper busbars.

| Property | 1350 Aluminum Bus Bar | 1060 Aluminum Bus Bar |

| Aluminum Content | ≥ 99.50% | ≥ 99.60% |

| Core Positioning | "Specialist" - Optimized for High Conductivity | "All-Rounder" - Balances conductivity, formability & corrosion resistance |

| Conductivity (20°C) | Approx. 61.0% IACS (International Standard Benchmark) | Approx. 61.0% IACS (Practically identical to 1350) |

| Key Difference | Strict Iron-Silicon Ratio (Fe/Si) requirement to minimize electrical resistance | No specific requirement for Fe/Si ratio; composition leans towards general workability |

| Mechanical Strength | Slightly lower strength, softer | Slightly higher strength than 1350, but still considered soft |

| Formability & Corrosion Resistance | Excellent | Slightly Superior. Theoretically better ductility and corrosion resistance due to marginally higher purity |

| Primary Standard | ASTM B236 (Standard for Electrical Bus Bar) | ASTM B210 (Drawn Tubes), etc.; more commonly a general-purpose material |

| Cost | May be slightly higher as a specialized electrical grade | Often more cost-competitive due to wide availability as a common industrial pure aluminum |

How to choose 1060 and 1350 aluminium busbars?

Prefer 1350 aluminum busbars when:

Applications: Used in critical power infrastructure such as large-capacity transformers, high-voltage switchgear, and long-distance power transmission, which are extremely sensitive to power loss.Core requirements: Pursue the ultimate in electrical conductivity and the lowest resistivity, even if the performance improvement is minimal.

Standard compliance: When project specifications or industry standards (such as ASTM B236) explicitly require the use of "electrical-grade" aluminum.

Reasons for selection: 1350 is a legitimate electrical aluminum. Its composition and processing are specifically optimized for electrical conductivity, providing the most reliable guarantee of the most important electrical properties.

Prefer 1060 aluminum busbars when:

Applications: Low-voltage distribution systems, distribution boxes, lithium battery connectors, and busbars in general industrial applications.Core requirements: Achieving a perfect balance between good conductivity, excellent formability (such as deep drawing), and corrosion resistance.

Cost Considerations: Pursuing optimal procurement costs and a wider material supply, while maintaining performance requirements.

Reasons for Selection: 1060 is an excellent and economical general-purpose high-purity aluminum material. Its electrical conductivity is comparable to 1350, sufficient for most applications, while offering slight advantages in workability and corrosion resistance.