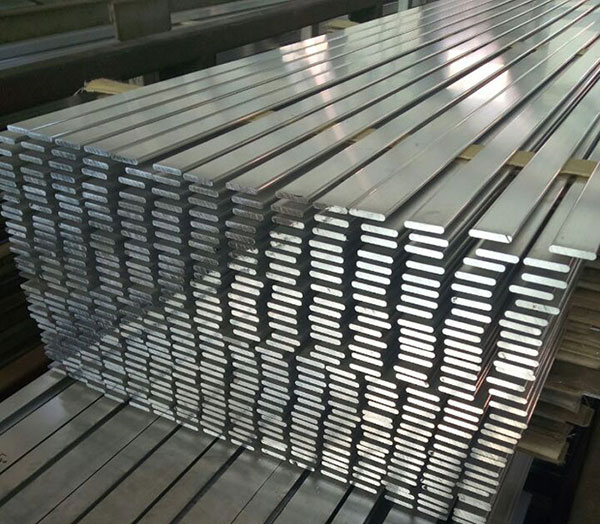

Buy Aluminum Flat Bar

Aluminum flat bar is a common profile, usually used in the fields of electricity and construction. How to choose a suitable aluminum row? As a manufacturer and exporter of aluminum rows for many years, Meisitu company give you some suggestions and solutions.

Before buy aluminum flat bars, you must first determine the following issues:

Material Grades: Aluminum flat bars are available in various grades and alloys, each with its own properties and applications. Consider factors such as strength, workability and weldability to select the alloy grade that best suits your project requirements.

The most common aluminum flat bar alloys : 1060 and 6061,what is difference between them:

Alloy temper:

1060 Aluminum flat bar: This is a pure aluminum alloy consisting of 99.6% aluminum and very small amounts of alloying elements. It is known for its excellent formability, high electrical conductivity and good corrosion resistance. However, it lacks the strength and hardness of some other aluminum alloys.

6061 Aluminum flat bar: This alloy is a heat-treatable aluminum alloy containing magnesium and silicon as the primary alloying elements. It has good strength, excellent corrosion resistance and weldability. Compared to 1060 aluminum, 6061 aluminum has higher mechanical properties due to its alloying elements.

Mechanical behavior:

1060 Aluminum flat bar: It has relatively low tensile strength and yield strength, making it suitable for applications where strength is not a primary consideration. However, it has good formability and ductility.

6061 Aluminum flat bar: This alloy exhibits significantly higher tensile and yield strengths compared to 1060 aluminum. It also has better hardness and workability, making it suitable for structural applications requiring greater strength and stiffness.

Application:

1060 Aluminum flat bar: Due to its excellent formability and high electrical conductivity, 1060 aluminum is commonly used in electrical conductors, heat sinks, reflective surfaces, architectural decoration and craft projects.

6061 Aluminum flat bar: Its higher strength and mechanical properties make 6061 aluminum suitable for a wide range of structural applications, including aerospace components, marine accessories, automotive components, bicycle frames and building structural components.

cost:

1060 Aluminum flat bar: Typically less expensive than 6061 aluminum due to its simpler alloy composition and lower manufacturing costs.

6061 Aluminum flat bar: The alloying elements in 6061 aluminum make it slightly more expensive than pure aluminum alloys like 1060, but its superior mechanical properties justify the higher cost for applications requiring strength and durability.

Electrical Conductors: The high electrical conductivity of 1060 aluminum makes it suitable for electrical conductors, such as busbars and electrical wiring.

Architectural Trim: 1060 aluminum flat bars are used in architectural trim, moldings, and decorative elements due to their lightweight nature, corrosion resistance, and ability to be easily shaped.

Determine the requirements you want: Before purchasing, understand the specific requirements of your project. This includes the dimensions (thickness, width, length) and grade/alloy of aluminum required. Factors such as strength, corrosion resistance and electrical conductivity also need to be considered.

Quality Assurance: Ensure the quality of the aluminum flat bars you purchase meets industry standards. Suppliers who can provide certification or have a good reputation are your first choice.

Surface Finish: Determine if you need aluminum flat bars with a specific surface finish. Some applications may require a smooth, polished surface, while others may require a rougher surface. Also identify any other surface treatments you may require, such as anodizing or painting.

Quantity and Pricing: Determine the quantity of aluminum flat bars you need for your project and compare prices from multiple suppliers. Buying in bulk may result in cost savings, but be sure to consider factors such as shipping costs and delivery time.

Supplier Reputation: Choose a reliable supplier with a strong reputation for quality products and excellent customer service.

Additional Services: Determine if you require any additional services, such as cutting, machining, or customization. Some vendors offer these services, which can save you time and effort.

Shipping and Delivery: Consider shipping costs, delivery times, and logistics when choosing a supplier. Choose a supplier that offers convenient shipping and can deliver aluminum flat bars to your location safely and on time.