New Energy Electric Vehicle Car

In terms of the battery range of electric vehicles, who can make a breakthrough will gain a huge market advantage. All battery manufacturers are looking for better materials and better processing technology. Basically, everyone agrees that soft connection is more advantageous for conductive connection.Especially LvPai soft connection on the battery conductive has more advantage, because the aluminum conductive capability is strong, it is important to its light quality, for new energy vehicles, before not find better energy storage materials for automotive weight is to increase the range, so aluminum favored by battery manufacturers, in the battery PACK, shell and cover are basically adopts pure aluminium material, molding method of metal stamping processing, less emissions when using sheet metal processing, low cost, processing speed, the battery was formed in series with the battery module, provide power for new energy vehicles.The flexible aluminum connection is widely used in connection with automobile parts.

Aluminium Busbar for New Energy Vehicle

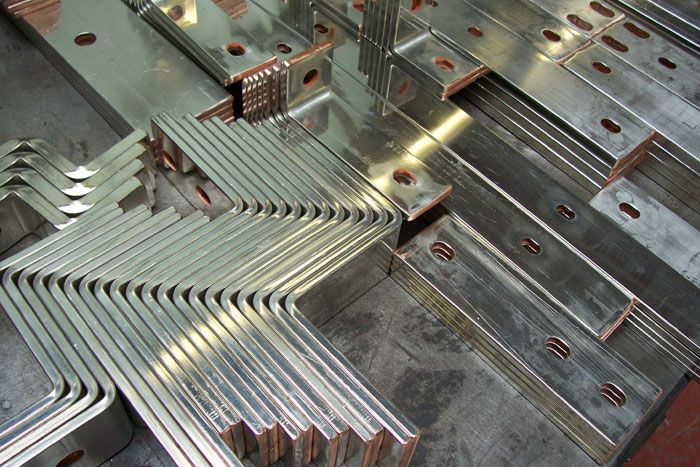

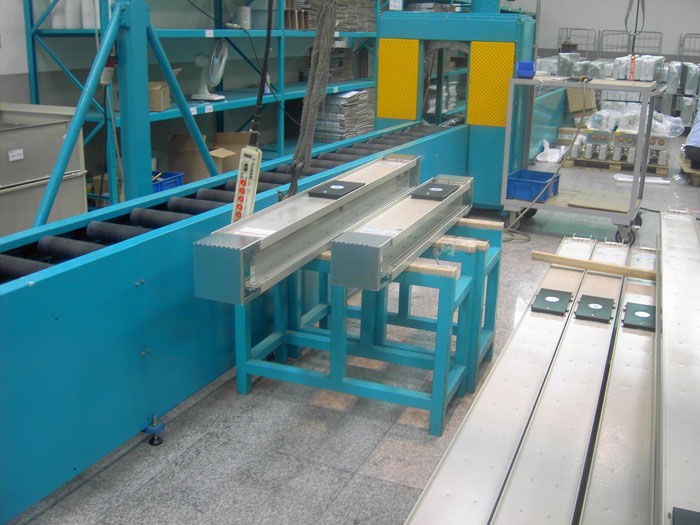

Process: moulding by molecular diffusion welding

Material: 1060 aluminum busbar

Structure: long * wide * high, processed (tin, silver and insulated bushing)

Advantages: anti-extrusion, bending, collision, manual bending, smooth and clean surface, no indentation, small section and easy installation

Performance

1. Good corrosion resistance, suitable for ultra-low temperature environment

2.Features of high conductivity, high load flow, good thermal conductivity, light weight, non-magnetic, easy to recover, etc.