Flexible Insulated Copper Busbar

Features of flexible insulated copper busbars

High Current Capacity: Supports continuous currents up to 1,200A with peak surges of 5,000A.Low Resistance: Premium oxygen-free copper (OFC) core minimizes energy loss.

Flexible Design: Bend radius as low as 30mm for tight spaces and curved installations.

Temperature Resistance: Operates safely at temperatures ranging from -40°C to +150°C.

UV/Chemical Resistance: Durable PVC/PET insulation withstands harsh environments.

Advantages of flexible insulated copper busbars

Space Efficiency: Compact profile reduces footprint in crowded systems.Ease of Installation: Pre-insulated design eliminates manual wrapping, saving time.

Safety: Triple-layer insulation (PVC fabric + insulation core) prevents short circuits.

Cost-Effective: Long lifespan and low maintenance reduce replacement costs.

Customizable: Available in lengths up to 50 meters and widths from 5mm to 50mm.

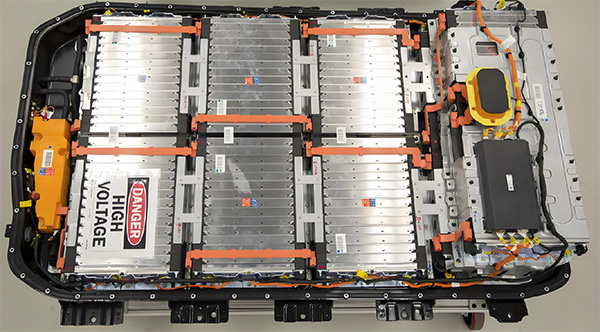

Application of flexible insulated copper busbars

Renewable Energy Systems: Solar inverters, wind turbines, and battery storage.

| Parameter | Details |

| Material | C11000 copper strip (copper content ≥ 99.95%, oxygen-free, high-purity electrolytic copper) |

| Single Strip Thickness | 0.8mm / 1mm (customizable within industrial standards) |

| Surface Finish |

- No plating (bare copper) - Tin plating (optional for enhanced corrosion resistance) |

| Insulating Material | PVC (Polyvinyl Chloride) or TPE (Thermoplastic Elastomer) |

| Insulation Color | Black (standard) |